Visiting The Paper Manufacturers At Hahnemühle

inspiration, brandbook, event

A few days ago we finally visited the artistic paper factory Hahnemühle on the countryside inDassel.

Dassel is located about 70 km north of Kassel „in the middle of nowhere“. With enormous vat machines and fourdrinier machines Hahnemühle produces handmage paper, watercolour paper, oiled paper, acrylic paper, sketch paper and pastel paper, as well as InkJet paper for professional photographers. Hahnemühle is known as the inventor of Digital Fine Art InkJet papers. Their artistic papers are finished off with a special ink-receptive coating, providing the perfect surface for durable prints with pigment ink in museum quality.

Hahnemühle is a real traditional business. Their roots go way back to the year 1584. Since then they’ve valued and preserved many parts of their manufatory. The raw materials for paper production are cellulose, water, chalk, starch and pigments (earthy colours) for colouring the papers.

The first hall is filled with bales of cotton from Alabama and pakets with bamboo fibers and pulp. The pulper, a huge vat with a mixer, is used to shred the pulp and mixes it with pure spring water from the Ilme, producing a pappy mass. This mass then is transferred to a container in which it is stirred mechanically, forming a homogenous mass. Adding the starch, chalk and pigments determines the character of the paper that can be tailored to the individual needs of every customer. Huge pipe systems transfer the mass directly to the paper machines. The quicker fourdrinier machines are used for most of the papers, the vat macines are only used for high-quality handmade paper. The techniques can be distinguished

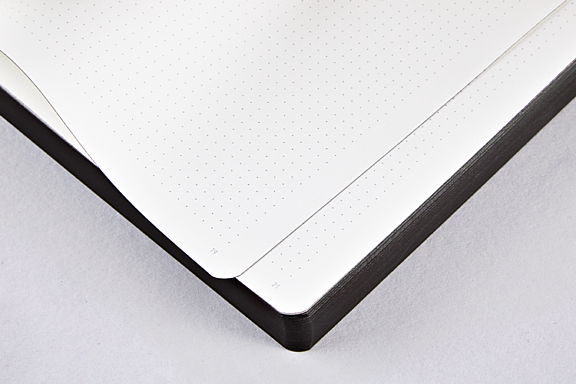

easily: While the fourdrinier machine is used by applying paper fibres in the running direction of the fourdrinier, the vat machine functions with a rotating cylinder, thus distributing the fibres disorderly. This production process is the more traditional, it takes more time (even the big machine only produces about 4 metres per minute), thus making more expensive high-quality paper. The

characteristic edge of the handmade paper is a result of flowing water. For the subsequent processing the paper is wrapped on a roll. For the sheet material there is a copper strip on the cylindrical sieve that prevents some fibre material from depositing - it's very similar to the process of producing watermarks. This is the part where the paper can be teared off. After that the paper rolls and paper sheets are brought to a huge hall where they are cut into

customary sizes and checked for quality. Finally, they are packed up.

There's a strange anecdote:

During World War II Hahnemühle was used to forge British banknotes - by the SS-Reichssicherheitshauptamt. It was the biggest counterfeiting action so far.

To us the visit was especially interesting because Hahnemühle produces small amounts of paper - aroung 3 tons - for individual customers according to their wishes. Now we only need a great project to use the paper!

For more information go to:

hahnemuehle.com

Hahnemühle is a real traditional business. Their roots go way back to the year 1584. Since then they’ve valued and preserved many parts of their manufatory. The raw materials for paper production are cellulose, water, chalk, starch and pigments (earthy colours) for colouring the papers.

The first hall is filled with bales of cotton from Alabama and pakets with bamboo fibers and pulp. The pulper, a huge vat with a mixer, is used to shred the pulp and mixes it with pure spring water from the Ilme, producing a pappy mass. This mass then is transferred to a container in which it is stirred mechanically, forming a homogenous mass. Adding the starch, chalk and pigments determines the character of the paper that can be tailored to the individual needs of every customer. Huge pipe systems transfer the mass directly to the paper machines. The quicker fourdrinier machines are used for most of the papers, the vat macines are only used for high-quality handmade paper. The techniques can be distinguished

easily: While the fourdrinier machine is used by applying paper fibres in the running direction of the fourdrinier, the vat machine functions with a rotating cylinder, thus distributing the fibres disorderly. This production process is the more traditional, it takes more time (even the big machine only produces about 4 metres per minute), thus making more expensive high-quality paper. The

characteristic edge of the handmade paper is a result of flowing water. For the subsequent processing the paper is wrapped on a roll. For the sheet material there is a copper strip on the cylindrical sieve that prevents some fibre material from depositing - it's very similar to the process of producing watermarks. This is the part where the paper can be teared off. After that the paper rolls and paper sheets are brought to a huge hall where they are cut into

customary sizes and checked for quality. Finally, they are packed up.

There's a strange anecdote:

During World War II Hahnemühle was used to forge British banknotes - by the SS-Reichssicherheitshauptamt. It was the biggest counterfeiting action so far.

To us the visit was especially interesting because Hahnemühle produces small amounts of paper - aroung 3 tons - for individual customers according to their wishes. Now we only need a great project to use the paper!

For more information go to:

hahnemuehle.com